How Industrial Scales Improve Efficiency in Manufacturing and Warehousing

How Industrial Scales Improve Efficiency in Manufacturing and Warehousing

Blog Article

Why to Pick Industrial Scales for Accurate Weight Measurement in Various Industries

In an era where accuracy is vital, the selection of commercial ranges for accurate weight dimension plays an essential function across varied industries. These scales not just enhance functional effectiveness but additionally make sure compliance with governing requirements, impacting whatever from production to delivery. Their robust layout and advanced modern technology provide to different applications, enhancing the demand for careful weight management. Comprehending the nuances of these ranges is essential for any organization aiming to enhance processes and mitigate pricey errors. The concern remains: what certain variables should one consider when selecting the right range for their distinct functional needs?

Importance of Accurate Weight Dimension

In the realm of industrial procedures, the significance of accurate weight measurement can not be overemphasized. Specific weight measurement is foundational throughout numerous sectors, influencing both functional performance and product high quality - Industrial Scales. It acts as a vital variable in inventory monitoring, guaranteeing that materials are adequately represented, consequently reducing waste and minimizing prices

In manufacturing, accurate weight measurement directly affects production processes. Anomalies in weight can lead to second-rate items or extreme resource allowance, impacting total earnings. Furthermore, in markets such as pharmaceuticals and food manufacturing, adherence to rigorous weight specs is important for regulatory conformity and customer safety and security.

In addition, exact weight dimensions promote efficient logistics and supply chain administration. Properly considered shipments ensure that transport prices are enhanced which stock levels are kept precisely, thereby protecting against supply shortages or overstock scenarios.

Sorts Of Industrial Scales

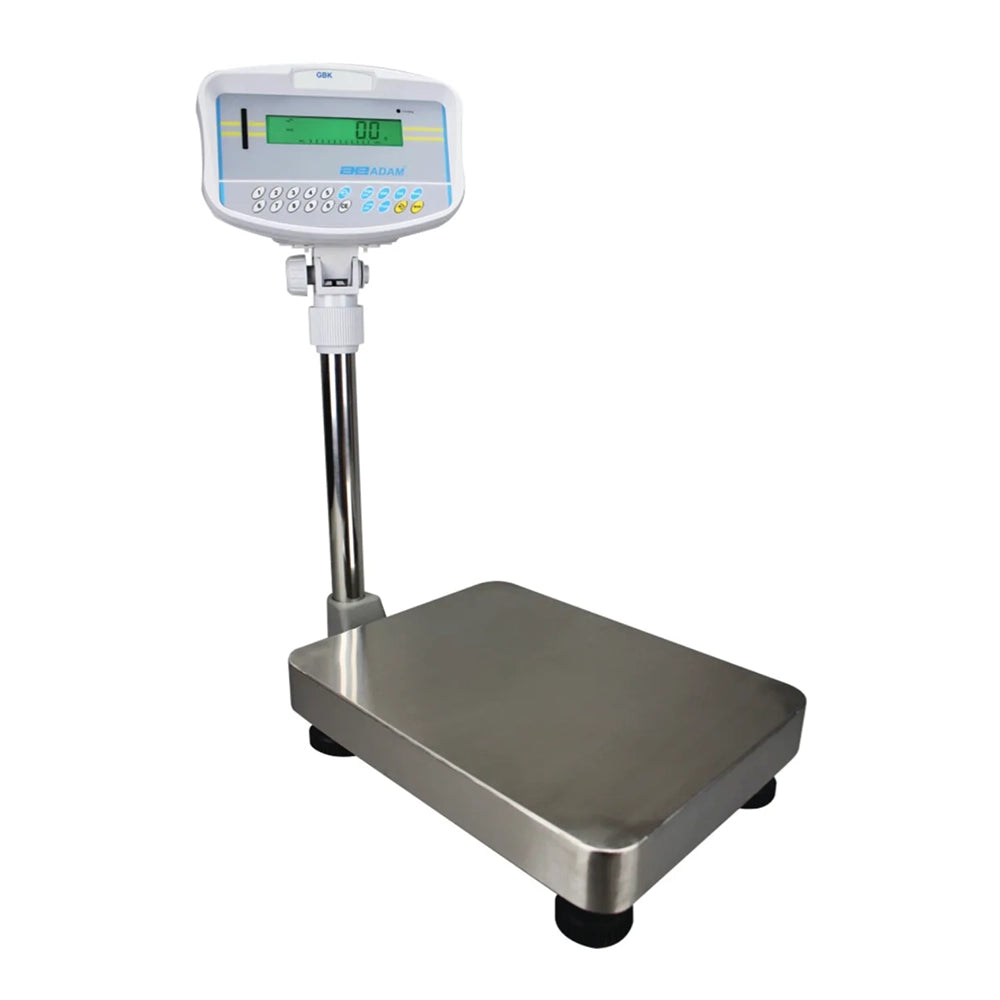

A wide array of industrial ranges are offered, each designed to fulfill particular dimension needs throughout diverse sectors. Common types consist of floor ranges, which are robust and appropriate for evaluating huge items or pallets in storehouses and distribution. Bench scales are smaller sized and optimal for lighter products, typically made use of in retail settings or producing for specific portion control.

One more group is portable scales, which supply the flexibility to be moved quickly around work sites, making them optimal for area operations or momentary arrangements. Precision scales, on the other hand, are made for high precision and are frequently used in labs and top quality control environments.

Load cells are important parts in numerous commercial ranges, converting push into an electric signal for exact analyses. In addition, truck scales supply the methods to weigh heavy cars and their tons, ensuring conformity with regulations and maximizing logistics.

Finally, checkweighers instantly contrast the weight of products against pre-programmed limitations, improving quality control in manufacturing lines (Industrial Scales). Each sort of commercial scale serves a special function, catering to the certain needs of markets such as manufacturing, logistics, food processing, and pharmaceuticals

Advantages of Making Use Of Industrial Scales

Regularly utilizing industrial ranges supplies substantial benefits throughout numerous fields. Among the main benefits is enhanced accuracy in weight dimension, which is essential for maintaining quality requirements and regulative compliance. Precise measurements prevent pricey mistakes in shipping, supply, and production administration, ultimately leading to raised operational efficiency.

Additionally, industrial ranges are developed for sturdiness and robustness, permitting them to stand up to severe settings usually found in production and warehousing. This resilience makes sure a long life expectancy, reducing the demand for frequent substitutes and read this maintenance prices.

Additionally, using industrial ranges improves security and lessens waste. By ensuring that items are evaluated properly, business can avoid overloading vehicles, which can cause penalties and crashes.

Applications Throughout Numerous Industries

Industrial scales play an essential function in various industries, including manufacturing, logistics, food handling, and drugs. In manufacturing, these scales are important for guaranteeing that raw materials are measured accurately, thus maintaining product top quality and uniformity (Industrial Scales). Precision in weight dimension straight affects production performance and expense management

In logistics, commercial ranges assist in the accurate considering of deliveries, which is important for adhering to maximizing and shipping regulations products costs. Exact weight data aids enhance operations and boosts supply chain management.

The food handling market counts heavily on commercial scales for compliance with wellness and safety laws. They are utilized to consider components precisely, making sure that formulations satisfy both quality criteria and legal demands. This is essential not only for customer security yet likewise for keeping brand honesty.

Pharmaceutical firms utilize commercial scales to make sure accurate dosages in medicine production, where even the least inconsistency can have significant repercussions. Compliance with stringent regulative standards makes accurate weight dimension vital in this field.

## Elements to Take Into Consideration When Selecting Scales

Choosing the right range for details applications requires careful consideration of a number of aspects. The ability of the range is essential; it should fit the optimum weight of the products being gauged without surpassing its restrictions. Additionally, the readability, or smallest increment the range can properly display, is important for precision, specifically in sectors where weight discrepancies can result in substantial economic losses or safety issues.

Ecological problems additionally play a substantial role in scale selection. As an example, scales used in humid or corrosive settings might call for customized materials to ensure sturdiness. In a similar way, mobility might be necessary in certain applications, demanding battery-operated and lightweight versions.

Conclusion

In conclusion, the selection of commercial ranges is essential for making certain exact weight dimension throughout varied markets. Thus, investing in premium industrial scales is vital for organizations aiming to make best use of and keep high requirements success.

Report this page